-

Home

-

Company

-

Products

-

News

-

FAQs

-

Blog

-

Contact

-

Phone

-

E-mail

-

Whatsapp

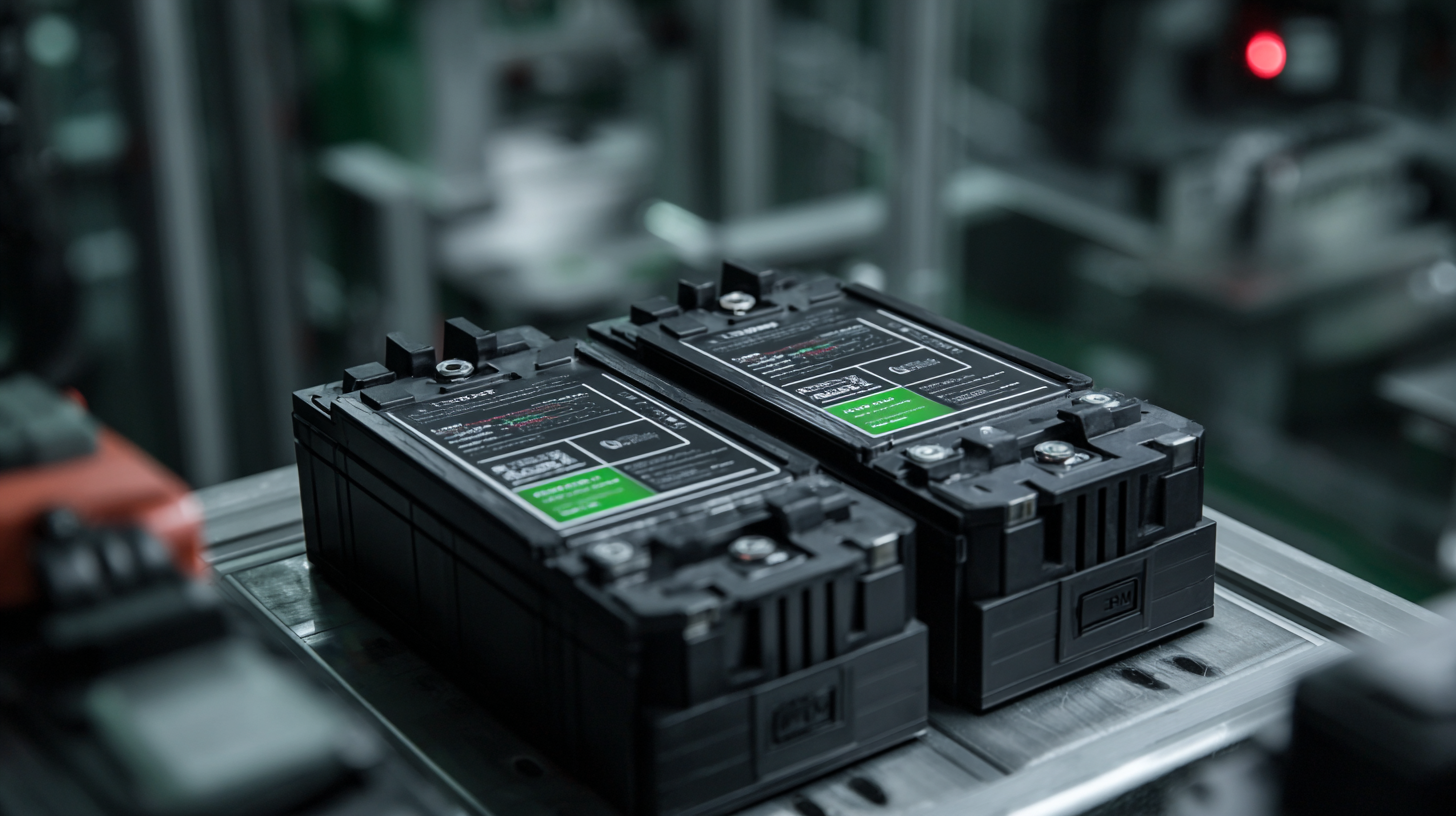

Leave Your Message

As renewable energy systems evolve, the integration of advanced battery technologies becomes crucial for maximizing efficiency and performance. The 48v 150amp Lifepo4 battery system is emerging as a leading choice for both residential and commercial applications, due to its remarkable energy density, long cycle life, and reliable safety profile. According to industry reports, lithium iron phosphate (LiFePO4) batteries can last up to 2,000 charge cycles, significantly outperforming traditional lead-acid batteries, which typically offer only around 500 cycles. Furthermore, the lightweight and compact design of the 48v 150amp Lifepo4 system makes it ideal for various energy storage solutions, from solar power installations to electric vehicles. By understanding and employing best practices for maximizing the efficiency of this battery system, users can unlock enhanced performance, lower operational costs, and contribute to a more sustainable future.

Maximizing charge cycle efficiency in a 48V 150A LiFePO4 battery system is crucial for extending battery life and ensuring optimal performance. To achieve this, it’s essential to monitor the state of charge (SOC) and avoid deep discharging. Keeping the battery within a range of 20% to 80% SOC can significantly enhance its lifespan and efficiency. Regularly checking the battery management system (BMS) for updates can also help optimize charging patterns and eliminate any potential issues early on.

Tips for maximizing efficiency include using a high-quality charger specifically designed for LiFePO4 batteries. This helps maintain the appropriate voltage levels and prevents overheating during charging. Additionally, ensure that all connections are clean and secure to reduce resistance, which can lead to energy loss. Implementing a scheduled maintenance routine can also help in detecting any irregularities in the system that may affect performance.

Lastly, consider installing a solar panel system to keep the battery topped off during extended periods of use. This not only reduces reliance on grid power but also promotes efficient energy usage by utilizing renewable resources. By integrating these strategies, users can greatly enhance the overall efficiency of their 48V 150A LiFePO4 battery system.

This chart illustrates the charge cycle efficiency of a 48V 150A LiFePO4 battery system over five cycles. The efficiency reflects how effectively the battery charges and discharges during each cycle.

Efficient load management is crucial when utilizing a 48V 150A LiFePO4 battery system, especially in applications requiring high energy output and reliability. By strategically distributing loads across multiple devices, you can reduce stress on individual components, thereby prolonging the lifespan of the battery system while maximizing its performance. Implementing a modular approach to load management not only enhances the system's output but also allows for effective monitoring and adjustments based on real-time usage patterns.

Recent advancements in technology emphasize the importance of optimizing resource efficiency. For instance, developments in AI and cloud computing have faced similar challenges of managing costs while maintaining performance. Techniques such as load balancing and multi-tier unloading have shown promise in optimizing resource allocation in various applications, paralleling the principles that can be applied to battery management systems. By adopting such innovative strategies, operators can achieve significant improvements in output performance, making the most out of their high-capacity battery systems.

Implementing effective thermal management solutions is crucial for extending the life of a 48v 150amp LiFePO4 battery system. One of the primary concerns with lithium iron phosphate batteries is their performance sensitivity to temperature fluctuations. High temperatures can accelerate degradation and reduce the overall cycle life, while excessively low temperatures can hinder charging and discharging efficiency. Incorporating a robust thermal management system helps maintain optimal operating temperatures, ensuring the battery remains efficient over its lifespan.

Active cooling systems, such as liquid cooling or heat exchangers, can be particularly beneficial for high-discharge applications. These systems help dissipate heat generated during operation and keep the battery within a desirable temperature range. Additionally, insulating the battery with materials that reflect heat can prevent unwanted temperature increases. Monitoring systems that provide real-time temperature readings can also play a vital role in battery management, allowing users to take proactive measures and adjust operations based on thermal data. By prioritizing thermal management, users can significantly enhance the reliability and longevity of their LiFePO4 battery systems.

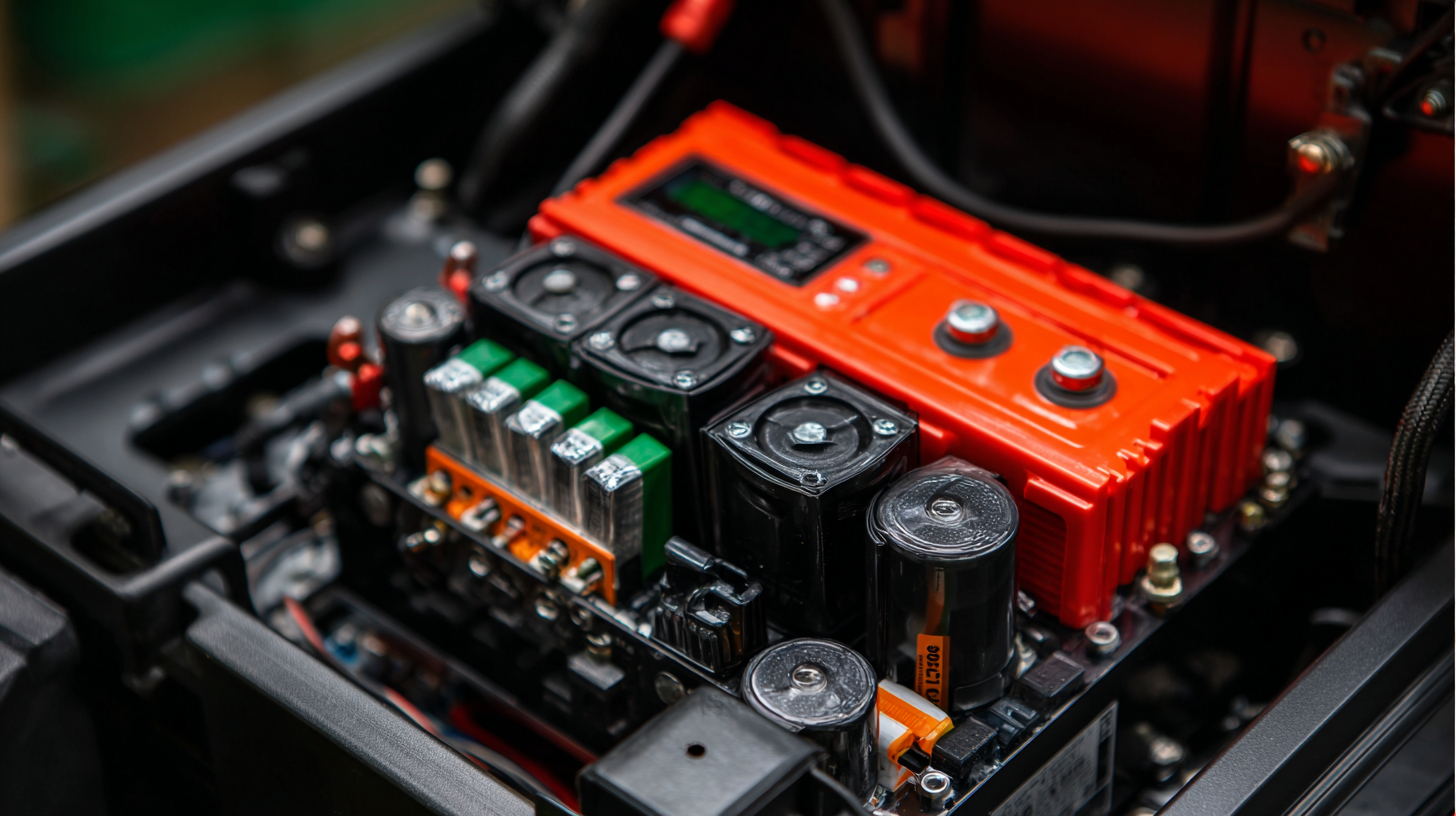

The integration of Battery Management Systems (BMS) in a 48V 150A LiFePO4 battery system is pivotal for ensuring real-time monitoring and fault prevention. A robust BMS improves efficiency by continuously assessing battery health and performance, allowing for proactive maintenance and management. According to a report by the International Energy Agency, battery systems equipped with advanced BMS technologies can extend battery life by up to 30%, significantly reducing total cost of ownership for users.

Real-time monitoring through BMS features enables users to track critical parameters such as state of charge, temperature, and voltage across individual cells. This data is essential because LiFePO4 batteries can degrade rapidly if any cell experiences over-voltage or excessive heat. Research from the Battery University indicates that overheating can reduce battery efficiency by as much as 20%, highlighting the importance of precise monitoring. By leveraging these technologies, operators can preemptively address issues before they escalate, ensuring their energy systems operate at optimal levels.

Furthermore, BMS systems can integrate with external systems for enhanced fault prevention. For example, predictive analytics algorithms can forecast potential failures by analyzing historical data trends. A study by the Energy Storage Association noted that implementing such proactive measures can reduce outages and increases system reliability by up to 15%. Therefore, utilizing BMS features not only maximizes the efficiency of a 48V 150A LiFePO4 battery system but also enhances its longevity and safety.

| Parameter | Value | Importance |

|---|---|---|

| Nominal Voltage | 48V | Standard for most applications |

| Nominal Capacity | 150Ah | Sufficient for high demand |

| Energy Density | 160 Wh/kg | High efficiency in space utilization |

| Cycle Life | 2000+ cycles | Long-term cost effectiveness |

| BMS Features | Real-Time Monitoring, Cell Balancing | Enhanced safety and performance |

| Temperature Range | -20°C to 60°C | Operational in diverse environments |

| Charge & Discharge Rate | 1C / 2C | Fast charging capability |

In the realm of renewable energy systems, maintaining the efficiency and longevity of a 48V 150A LiFePO4 battery setup hinges significantly on implementing robust maintenance strategies. According to a report from the International Energy Agency (IEA), regular maintenance can enhance system reliability by up to 30%, reducing the risk of unexpected failures. Key maintenance practices include routine battery health checks, where voltage levels, internal resistance, and temperature are monitored to ensure that they align with manufacturer specifications.

Moreover, optimal charging techniques play a critical role in the longevity of LiFePO4 batteries. The Battery University suggests that keeping the charging voltage within recommended limits—ideally between 3.2V to 3.6V per cell—can extend the cycle life significantly, potentially reaching over 3000 cycles compared to less than 2000 with improper charging. Additionally, periodic cleaning of battery terminals and ensuring proper ventilation can mitigate issues related to corrosion and overheating. By prioritizing these maintenance strategies, users can ensure consistent performance and reliability from their battery systems in the long run.